Felicia Larsson

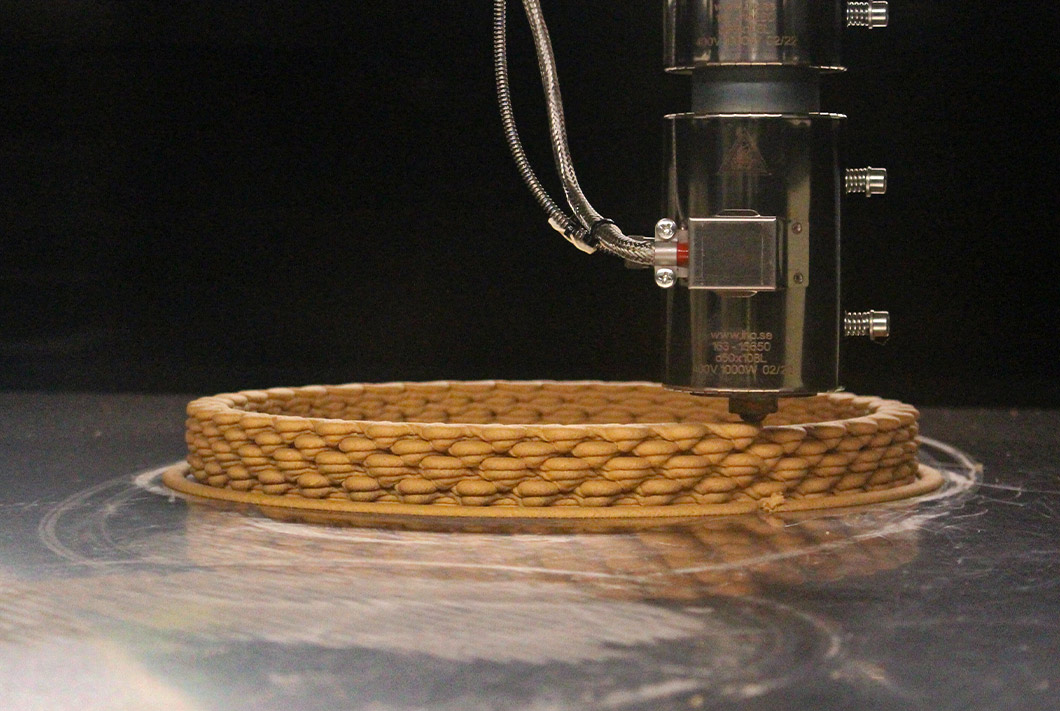

Integrating additive manufacturing with biocomposites opens up possibilities for a local, flexible, and resource-efficient process suited to smaller-scale production and customised products. 3-D printing techniques are becoming more common and call for new business models, designs and testing to make the process successful, sustainable and cost-efficient.

My degree project is carried out in collaboration with Stora Enso, a company that produces and develops solutions based on wood and biomass. Most of the project has been conducted in Hyltebruk where Stora Enso´s factory of biocomposite is located and where I have been able to access a large 3-D printer to explore and test ideas.

In addition to identifying a setting where printed objects could be suitable for Stora Enso’s circular service OneLoop, my aim has been to create a collection of products that match each other visually and demonstrate different possibilities with the circular service system and the manufacturing technique.